CNC Aluminum Parts In Automobile And Soalr System

CNC Aluminum Parts In Automotive Motor Housing

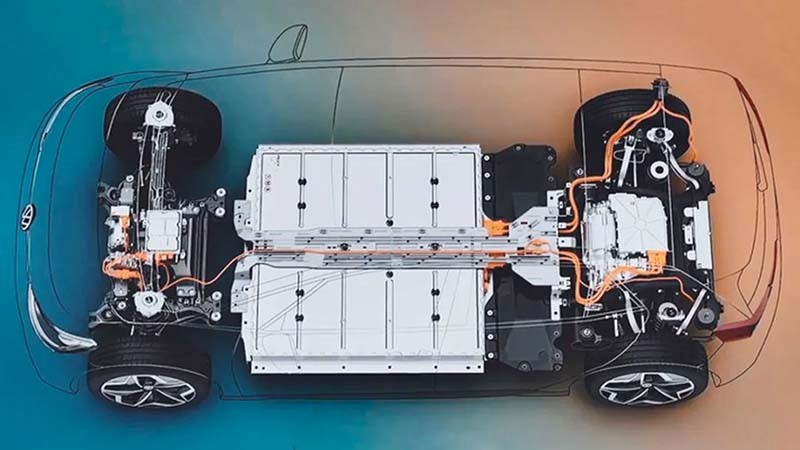

The motor housing is the device that protects the internal DC motor body from dust and damage. These motor housings also provide the motor with reliable and consistent function and desirable performance. These motor housings are manufactured using a top quality material so they are strong and durable. These motor housings are of excellent shape and size, allow the motor to be installed in them easily and reliably, and can be adjusted very well in the most ideal and most desired way.

The manufacturing of automotive motor housing casting covers for new energy vehicles. The motor housing casting cover serves as a protective enclosure for the motor components, providing mechanical support and ensuring the motor’s reliable operation. CNC (Computer Numerical Control) machining is a precise and efficient manufacturing process that uses computer-controlled machines to shape and form metal parts.

Aluminum is a favored material for motor housing casting covers due to its lightweight nature, excellent thermal conductivity, corrosion resistance, and high strength-to-weight ratio. It allows for efficient heat dissipation, which is crucial for maintaining optimal motor performance. CNC machining involves the use of computer-controlled machines to precisely cut, shape, and form aluminum parts according to design specifications. The process can include operations such as milling, drilling, turning, and threading, among others, to create complex and accurate components. Besides, it offers high precision and versatility, allowing for the production of customized motor housing casting covers that precisely fit the specific motor and vehicle requirements. The computerized control ensures consistent and accurate manufacturing results.

CNC aluminum parts for motor housing casting covers can be designed to include features such as mounting holes, flanges, or threaded inserts to facilitate easy integration and secure attachment to the motor and vehicle chassis. Meanwhile, CNC machining allows for precise control over dimensions, tolerances, and surface quality. Quality control measures, such as inspections and testing, are implemented throughout the manufacturing process to ensure that the CNC aluminum parts meet the required specifications and standards.

CNC Aluminum Parts In Solar System

SJHM’s aluminum CNC machine parts find extensive use in the automotive industry. They are employed in the manufacturing of engine components, transmission parts, suspension components, intake manifolds, brackets, and various other automotive systems. Aluminum parts offer benefits such as weight reduction, improved fuel efficiency, and enhanced performance. SJHM aluminum CNC machine parts are also employed in the renewable energy sector, particularly in the manufacturing of motor housing cover and solar power systems. Aluminum components are used in wind turbine blades, hubs, frames, and solar panel mounting systems. Aluminum’s lightweight nature, corrosion resistance, and ease of machining make it a favorable choice for renewable energy applications.

Solar Panel Frames: Aluminum is widely used in the construction of solar panel frames. The frames provide structural support to the solar panels, protecting them from mechanical stresses and facilitating their installation. Aluminum’s lightweight nature, corrosion resistance, and ease of fabrication make it an ideal material for solar panel frames.

Mounting Systems: Aluminum is used in the production of mounting systems that secure solar panels to various surfaces, such as rooftops or ground mounts. These mounting systems typically consist of aluminum rails, brackets, clamps, and connectors. Aluminum’s strength and durability ensure the stability and longevity of the solar panel installation.

Racking Systems: Racking systems are used to support and position solar panels in large-scale solar installations. Aluminum is commonly used in the construction of racking systems due to its lightweight nature, corrosion resistance, and ease of installation. Aluminum racking systems are designed to withstand environmental factors and provide optimal panel orientation for maximum energy generation.

Solar Trackers: Solar trackers are devices that follow the sun’s movement throughout the day to optimize the solar panel’s angle of incidence. Aluminum components are often utilized in solar tracker structures due to their high strength-to-weight ratio, allowing for efficient tracking mechanisms that reduce energy loss and increase overall system performance.

Electrical Enclosures: Aluminum is used in the fabrication of electrical enclosures for solar systems. These enclosures house electrical components, such as inverters, charge controllers, and junction boxes, providing protection against environmental factors and ensuring electrical safety. Aluminum enclosures offer durability, corrosion resistance, and effective heat dissipation.

Grounding and Bonding Components: Aluminum is used in grounding and bonding components in solar systems. These components ensure the electrical safety of the system by providing a path for electrical current to safely flow into the ground. Aluminum grounding lugs, clamps, and connectors are commonly employed for their electrical conductivity and corrosion resistance.

Heat Dissipation Components: Solar systems generate heat during operation, especially in the case of concentrated solar power (CSP) systems. Aluminum heat sinks and heat spreaders are used to dissipate excess heat from power electronics, such as inverters, ensuring their optimal performance and longevity.

SJHM’s cnc machine parts are widly applied into as aluminum’s properties for its lightweight nature, corrosion resistance, recyclability, and ease of fabrication, make it an ideal choice for various components in solar systems. The use of aluminum parts helps enhance the overall efficiency, durability, and sustainability of solar energy installations.