The Benefits of Chemical Imaging System

Chemical imaging systems are one of the most exciting developments in the chemical industry. These systems allow you to see inside a container and detect contaminants that may be lurking there. Chemical imaging system also could be used to screen for microplastics in food and water sources, which would help to reduce human exposure to these pollutants. The system could also be used to monitor microplastic pollution in the environment over time, helping to assess the efficacy of clean-up efforts and a lot more.

Technologies like chemical imaging system have been used for decades, but they have recently become more popular with many companies looking to improve their safety programs by using them. To understand what makes chemical imaging systems so effective, here are some of their benefits.

Determine effectiveness

The use of chemicals has become increasingly common over time as firms continue to try new ways to get things done more efficiently. However, not all chemicals are created equal when it comes to their usefulness or effectiveness; some will work better than others while others will be worse than useless altogether!

That’s where chemical imaging systems come into play because they can help determine which chemicals are best suited for particular jobs or situations—which means less wasted time and money on trying out different substances before finding something useful instead!

Safety

Chemical imaging equipment can provide important information about the levels of harmful substances in containers that could lead to accidents or even fatalities if not detected. For example, high levels of chlorine in a pool could cause an adverse reaction if someone were exposed to it during swimming or diving activities—and it is possible that no one would know about this problem until after someone was hurt by it! By having such information on hand through chemical imaging equipment, companies can take corrective action before there is any serious harm caused by an accident.

Allows researchers to map the chemical composition, structure, and properties of a material.

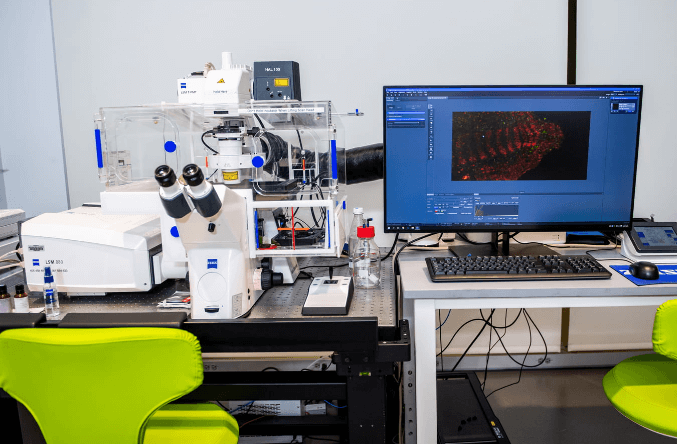

Chemical imaging is a new form of spectroscopy that allows researchers to map the chemical composition, structure, and properties of a material. It combines both optical microscopy and X-ray diffraction techniques to produce images with high spatial resolution and broad wavelength coverage.

Chemical imaging systems work by using x-ray energy (typically between 0.5 – 5 keV) to induce fluorescence from molecules within a sample. This can be achieved through either synchrotron radiation or optical excitation methods depending on the type of analyte being studied

Combine chemometrics with chemical analysis to visualize data

Chemometrics is the use of mathematical and statistical techniques to extract information from a chemical spectrum. It can be used to analyze data from all types of mass spectrometry, including GC/MS and LC/MS, as well as other detectors such as UV-Vis spectroscopy or fluorescence microscopy.

Most chemical imaging systems use infrared light that is invisible to the human eye. This means there’s no need for special safety precautions or protective eyewear when using such equipment. Chemometrics is the use of mathematical and statistical techniques to extract information from a chemical spectrum. It can be used to analyze data from all types of mass spectrometry, including GC/MS and LC/MS, as well as other detectors such as UV-Vis spectroscopy or fluorescence microscopy.

Improves your research

Chemical imaging is the process of applying a chemical to a surface, then detecting changes in the chemical’s properties due to interactions with that surface. This information can be used for a variety of purposes:

- Quality control – Chemical imaging allows you to check whether your product contains what it says on its label. It also allows you to determine if any impurities have been added during processing or manufacturing, which may cause problems down the line.

- Process monitoring – If your company produces multiple products at different stages in their lifecycle, chemical imaging can help track these processes from the beginning until end-of-life (EOL). For example, if you want more accurate information about how much energy each part requires during production—and therefore how much CO2 emissions will result—chemical imaging would be invaluable here because it creates an image showing exactly where each piece goes as well as what happens when it gets there without losing any details along the way!

- Raw material quality control – If there are certain materials used in one part but not others within another component; then using this technology will allow us to identify those differences immediately since everything else looks similar enough.

Rapid and non-invasive analysis

Chemical imaging systems are non-invasive, This means that it doesn’t degrade the tested sample, which is crucial in situations when samples are uncommon or irreplaceable. This can save time and money, which is especially important if you’re taking a lot of samples at once.

Chemical imaging systems enable rapid and non-invasive analysis of the chemical composition, making it possible to identify unknown substances in a matter of seconds. Chemical imaging technology has been used to study everything from pharmaceuticals and foodstuffs to cancerous cells and bone tissue. It can also be employed by engineers working on materials such as polymers, ceramics, and coatings.

Chemical imaging systems are used for hundreds of applications

Chemical imaging systems are used for non-invasive analysis with hundreds of applications. They allow researchers to map the chemical composition, structure, and properties of a material in real-time and at high spatial resolution. The technology is based on Raman spectroscopy, where energy from an electromagnetic or laser source excites the vibrational motion of molecules so that they can be imaged by an optical microscope.

Conclusion

Chemical imaging system help industries manage their inventory, make more informed decisions, and reduce costs. These tools provide information about the condition of a product or material at any given time, which can help businesses optimize their processes. This kind of equipment is reasonably priced and can be paid for just in time savings. Consider making an investment in one right away if you’re looking for ways to grow your company.