Mastering Productivity: Enhancing Your Spray Foam Rig Configuration

A well-organized spray foam rig setup can significantly enhance productivity and effectiveness in insulation projects. We will delve into strategies and techniques for maximizing efficiency, ensuring that every component of your rig is optimized to deliver top-notch results. From equipment selection to layout design and maintenance, we’ll cover key aspects to help you streamline operations and achieve peak performance in your spray foam applications.

Selecting the Right Equipment

Choosing the appropriate equipment is the cornerstone of an efficient spray foam rig setup. Start by assessing your project requirements and selecting machines that align with your workload and insulation needs. Consider factors such as spray output, pressure capabilities, heating systems, and compatibility with various foam types. Opt for reliable brands known for durability and performance. Invest in quality hoses, guns, and accessories that complement your primary equipment. Having the right tools enhances productivity and contributes to consistent and high-quality foam applications.

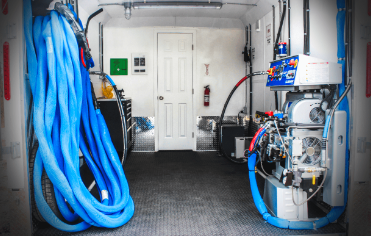

Optimizing Rig Layout and Organization

The efficient layout and organization of your perfect spray foam rig for sale at Profoam Corporation can significantly impact workflow and productivity. Designate clear zones for different functions, such as storage, mixing, spraying, and maintenance. Arrange equipment logically to minimize movement and time wastage during operations. Ensure easy access to essential components, such as drums, pumps, and safety gear, to facilitate smooth workflow transitions. Implement color-coded labels or visual cues to identify materials and streamline inventory management. Regularly review and refine your rig layout based on user feedback and evolving project needs to optimize efficiency continually.

Read also: Taking It To The Next Level: Advanced Techniques For Basketball Training

Streamlining Material Handling and Storage

Efficient material handling and storage practices are vital for maximizing productivity in spray foam applications—store foam components in a controlled environment to maintain optimal temperature and prevent contamination. Use designated racks or shelves to organize drums and containers for easy access and inventory management. Implement a systematic approach to material handling, including proper mixing procedures, waste minimization strategies, and safe disposal practices. Train your team on handling protocols and safety measures to reduce errors and downtime during material preparation and application. Regularly audit and replenish supplies to ensure uninterrupted workflow and project continuity.

Implementing Maintenance and Quality Control Protocols

Regular maintenance and quality control protocols are essential for peak spray foam rig setup performance. Develop a comprehensive maintenance schedule for all equipment components, including pumps, hoses, guns, and heating systems. Conduct routine inspections, calibration checks, and performance tests to detect and address potential issues proactively. Implement quality control measures, such as batch testing and foam quality assessments, to maintain consistency and adherence to industry standards. Train your team on equipment maintenance, troubleshooting techniques, and quality assurance practices to minimize downtime and optimize productivity during projects.

Utilizing Technology and Automation

Integrating technology and automation can revolutionize the efficiency of your spray foam rig setup. Consider investing in intelligent controllers or monitoring systems that offer real-time data on spray parameters, temperature, and pressure. Automated mixing and proportioning systems can streamline material preparation, reduce waste, and enhance consistency in foam application. Explore software solutions or mobile apps that enable project management, scheduling, and inventory tracking for seamless workflow coordination. Embrace digital tools and innovations to optimize processes, improve accuracy, and empower your team with actionable insights for enhanced productivity.

Read also: Maximize Your Water Efficiency With A Smart Lawn Irrigation System

Training and Skill Development

Investing in training and skill development for your team is paramount to maximizing efficiency in spray foam applications. Provide comprehensive training programs on equipment operation, safety protocols, mixing techniques, and troubleshooting procedures. Encourage continuous learning and skill enhancement through workshops, certifications, and industry conferences. Foster a culture of collaboration and knowledge sharing among team members to leverage collective expertise and problem-solving capabilities. Empower your workforce with the skills and confidence to tackle challenges efficiently, mitigate risks, and deliver superior results in every insulation project.

Monitoring Performance Metrics and Feedback

Tracking performance metrics and gathering feedback is crucial for improving and optimizing your spray foam rig setup. Utilize performance analytics tools to monitor critical indicators such as material consumption, application rates, downtime incidents, and project timelines. Analyze data trends to identify areas for improvement, operational bottlenecks, or equipment optimization opportunities. Solicit feedback from your team, clients, and industry peers to gain insights into operational challenges, customer satisfaction levels, and emerging trends. Use this feedback loop to implement targeted improvements, refine processes, and continuously adapt strategies to enhance productivity and performance.

Mastering productivity in spray foam applications requires a holistic approach encompassing equipment selection, rig layout optimization, material handling efficiency, and robust maintenance protocols. By implementing the strategies outlined, you can enhance workflow efficiency, minimize downtime, and deliver exceptional results in your insulation projects. Continuously evaluate and refine your rig setup based on performance feedback and industry advancements to stay ahead and maximize productivity in the dynamic field of spray foam applications.