How to Choose the Best 3D Printing Slicer Software

The world of 3D printing is nothing short of remarkable, allowing us to turn digital designs into tangible objects. At the heart of this transformative technology lies slicer software, a vital tool for translating your designs into precise instructions for 3D printers. But with a multitude of slicer software options available, how do you choose the best one for your needs? This guide is your key to unlocking the power of 3D printing by selecting the ideal slicer software.

1. Compatibility with Your 3D Printer

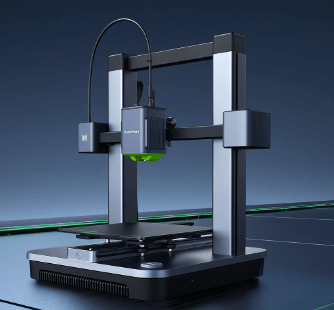

One of the first considerations when choosing slicer software is compatibility with your 3D printer. Some slicer programs are optimized for specific printer models, so check if your printer is supported. For example, AnkerMake 3d printer slicer software is recommended for AnkerMake M5 series of 3D printers. Additionally, many slicer software options allow you to create custom printer profiles, which can be invaluable if your printer is not in the database.

2. Ease of Use

Slicer software varies in terms of user-friendliness. If you’re new to 3D printing, you may want to start with a beginner-friendly slicer like Ultimaker Cura and AnkerMake. For those with more experience, you might opt for advanced software like PrusaSlicer or Simplify3D.

3. Features and Customization

Consider the features offered by the slicer software. Advanced users might look for extensive customization options, allowing you to fine-tune print settings. These settings can include layer height, print speed, infill density, support structures, and more. Software like MatterControl and IdeaMaker offers deep customization options.

4. Supported File Formats

Ensure that your chosen slicer software supports a wide range of file formats. STL (stereolithography) files are standard, but you may also want compatibility with other formats like OBJ or 3MF. A diverse range of supported formats ensures you can work with different design software and files.

5. Regular Updates

Regular software updates are crucial for fixing bugs, enhancing performance, and adding new features. Choose slicer software with a history of consistent updates, as this ensures long-term usability and compatibility with evolving 3D printing technology.

6. Print Previews

A visual print preview feature can be incredibly helpful. It allows you to inspect each layer of your print before initiating the printing process. This way, you can identify potential issues and make adjustments before the printer even starts.

7. Material Profiles

Different 3D printing materials require specific print settings. Many slicer software options come with pre-configured material profiles for common materials like PLA, ABS, PETG, and more. Having these profiles at your disposal simplifies the setup process.

8. Community and Support

Joining a community of users who can share experiences, tips, and solutions can be highly beneficial. Some slicer software has active online communities. Additionally, check if the software has accessible customer support or forums where you can seek help when needed.

9. Cost Considerations

Lastly, consider your budget. Slicer software varies in price, with some excellent open-source options like the AnkerMake Slicer available for free. Commercial software, like Simplify3D, offers more advanced features but comes with a price tag. Evaluate your needs and budget to make an informed decision.

In Conclusion

Totally speaking, the slicer software you choose can significantly impact your 3D printing experience. Selecting the best one for your specific needs and expertise level is crucial. Keep in mind compatibility, ease of use, features, supported file formats, updates, print previews, material profiles, community support, and cost considerations when making your decision. Whether you’re a 3D printing novice or an experienced enthusiast, the right slicer software can be the key to unlocking your creative potential in the world of 3D printing.