Advanced Techniques with Double-Head Single Needle Quilting

Yuantian double-head quilting machine is a type of industrial sewing machine specifically designed for quilting tasks. Quilting machines are used to stitch together the layers of a quilt, which typically include the quilt top, batting, and backing fabric. These machines are equipped with features that make quilting more efficient and precise compared to traditional sewing machines. The primary characteristic of a double-head quilting machine is that it has two quilting heads mounted on the machine. These heads can operate simultaneously, allowing for the quilting of two separate sections of fabric at the same time. The use of dual quilting heads significantly increases the machine’s productivity. It can complete quilting projects in less time compared to a single-head machine, making it suitable for high-volume production.

The double head quilting machine is a state-of-the-art apparatus designed for quilting fabrics with precision and efficiency. Unlike traditional quilting methods that require extensive manual labor, this machine streamlines the process by automating intricate stitching patterns. Its primary purpose is to enhance productivity and deliver high-quality quilts with impeccable design. The world of textile manufacturing has witnessed a remarkable transformation with the advent of advanced machinery. Among these innovations, Yuantian double-head quilting machine stands out as a revolutionary tool in the realm of quilting and textile artistry. Many modern double-head quilting machines come equipped with computerized controls. This technology allows for precise programming of quilting patterns, adjustments of stitching parameters, and the automation of the quilting process.

Features And Capabilities:

These machines often offer a wide range of quilting patterns, from simple geometric designs to more intricate and decorative patterns. The ability to switch between patterns easily makes them adaptable to various quilting projects. Some double-head quilting machines feature automatic thread trimming capabilities. This reduces the need for manual intervention after each quilting cycle, streamlining the overall quilting process. The machine may be equipped with a user-friendly touchscreen interface. This interface allows operators to input quilting patterns, adjust settings, and monitor the quilting process with ease. The use of two quilting heads does not compromise the precision and consistency of the stitching. Each head typically operates independently, ensuring that the quilting results meet high-quality standards. In a word, Double-head quilting machines find applications in industries where efficient and high-quality quilting is essential, including textile manufacturing, bedding production, and furniture upholstery.

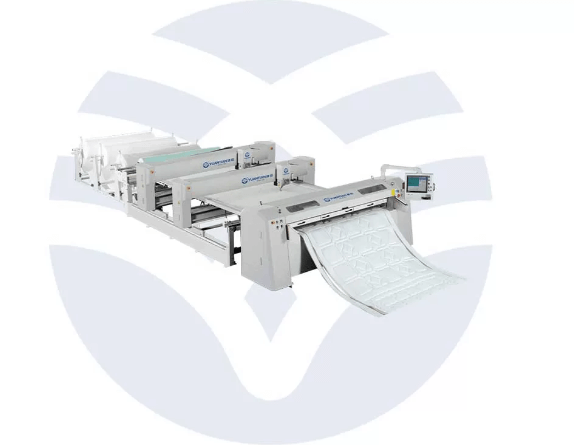

Double-head Single Needle Quilting Machine YT-DZHF-2G

The machine is equipped with two quilting heads, allowing it to simultaneously work on two separate sections of fabric. This dual-head design significantly increases the machine’s throughput and efficiency. Despite having two quilting heads, each head is designed to use a single needle. This configuration maintains precision in stitching while allowing for the simultaneous quilting of two sections of fabric. The dual-head feature enhances productivity by quilting two sections of fabric at the same time. This is particularly beneficial for high-volume production environments where speed is essential. Yuantian double-head single needle quilting machines are versatile and can handle various types of fabrics. They are suitable for quilting different products, including bedspreads, comforters, and upholstery.

Many modern quilting machines, including double-head single needle models, come with computerized controls. This technology allows for precise programming of quilting patterns, making it easier to switch between different designs. Many modern quilting machines, including double-head single needle models, come with computerized controls. This technology allows for precise programming of quilting patterns, making it easier to switch between different designs. These machines typically offer a range of quilting patterns, from basic designs to more complex and decorative ones. The operator can select and program the desired patterns using the machine’s control interface. Some models of double-head single needle quilting machines feature automatic thread trimming capabilities. This reduces manual intervention and streamlines the quilting process.

When operating the double-head single needle quilting machine, operators should follow the Yuantian‘s guidelines and instructions for setup, threading, maintenance, and safety. Regular maintenance and proper training are essential to ensure optimal performance and longevity of the machine. The single needle design in each quilting head ensures precise stitching. The independent operation of each head contributes to consistent and high-quality results. If your machine has computerized controls, program the desired quilting pattern. Adjust other settings such as stitch length and speed according to your requirements. Before quilting the actual project, perform a test run on a scrap piece of fabric. This allows you to check the tension, stitching accuracy, and overall machine performance.